Static Conductive Tank Truck Composite Hose

Composite Tank Truck Hose: Engineered for tankers and dock loading. It delivers 4.0 MPa high-pressure, static conductivity, and extreme temperature resilience -30°C to +120°C. The multi-layer construction and strict safety compliance ensure reliable and efficient transfer of petroleum and chemical products.

Premium Tank Truck Composite Hose

Heavy-Duty Oil Transfer Solution for Dock Loading & Tanker Operations

CONTACT USEngineered for Demanding Applications

Evergood composite hoses are specifically designed for safe and efficient petroleum product transfer in tank truck operations and dock loading facilities. Combining flexibility, durability, and chemical resistance, these hoses deliver reliable performance in the most challenging environments.

Built with multiple reinforcement layers and advanced sealing technology, our hoses ensure leak-free operation while maintaining flexibility even under extreme temperature conditions ranging from -30°C to +120°C.

Key Features & Benefits

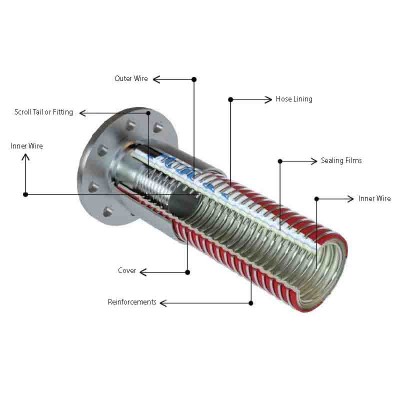

Multi-Layer Construction

Advanced composite design with inner wire reinforcement, multiple fabric layers, and outer wire helix for superior strength and flexibility.

Chemical Resistant

Compatible with a wide range of petroleum products including gasoline, diesel, kerosene, and various hydrocarbon-based fuels.

Temperature Range

Operates reliably from -30°C to +120°C, maintaining flexibility and structural integrity in extreme weather conditions.

Static Conductive

Built-in electrical conductivity prevents static buildup during fuel transfer, ensuring safe operations and compliance with safety regulations.

High Pressure Rating

Working pressure up to 4.0 MPa for most sizes, ensuring safe handling of high-flow petroleum transfer operations.

Durable & Lightweight

Combines robust construction with lightweight design for easy handling during dock operations and tanker loading procedures.

Technical Construction

The Technical Construction of Tank Truck composite hose

Liner: multiple layers of PTFE films.

Carcass: multiple layers of polypropylene fabrics, films and polyester barrier layers.

Cover: abrasion resistant PVC coated fabric.

Technical Specifications

| DN (mm) | Bend Radius (mm) | Working Pressure (Mpa) | Weight (Kg/m) | Working Temperature (℃) | Length (MAX) |

|---|---|---|---|---|---|

| 32 | 240 | 1.6-4.0 | 1.9 | -30~120 | 40m |

| 40 | 280 | 1.6-4.0 | 2.25 | -30~120 | 40m |

| 50 | 310 | 1.6-4.0 | 2.5 | -30~120 | 40m |

| 80 | 360 | 1.6-4.0 | 2.8 | -30~120 | 40m |

| 100 | 450 | 1.6-4.0 | 3.9 | -30~120 | 40m |

| 125 | 560 | 1.6-4.0 | 4.5 | -30~120 | 40m |

| 150 | 720 | 1.6-4.0 | 5.5 | -30~120 | 40m |

| 200 | 860 | 1.6-4.0 | 8.5 | -30~120 | 40m |

| 300 | 950 | 1.6-4.0 | 15 | -30~120 | 40m |

| 350 | 980 | 0.8-2.5 | 16 | -30~120 | 40m |

| 400 | 1000 | 0.8-2.5 | 18 | -30~120 | 40m |

| 500 | 1050 | 0.8-2.5 | 20 | -30~120 | 40m |

| 600 | 1150 | 0.8-2.5 | 24 | -30~120 | 40m |

| 700 | 1250 | 0.8-2.5 | 30 | -30~120 | 40m |

| 800 | 1500 | 0.8-2.5 | 35 | -30~120 | 40m |

Primary Applications

Refinery Operations

Internal product transfer within petrochemical processing facilities

Fuel Distribution

High-volume fuel delivery to storage facilities and distribution centers

Safety & Compliance

Industry Standards

Tank truck composite hose manufactured in compliance with international petroleum handling standards and regulations for safe oil transfer operations.

Static Grounding

Tank truck hose built-in electrical conductivity with proper grounding capabilities to prevent dangerous static discharge during fuel transfer.

Leak Prevention

Multiple sealing film layers and precision manufacturing ensure zero-leak performance throughout the product lifecycle.

Quality Testing

Every composite hose undergoes rigorous pressure testing, flexibility testing, and quality inspection before shipment.

Why Choose Our Composite Hoses

Proven Reliability

Trusted by major oil terminals and tanker fleets worldwide for demanding petroleum transfer applications. Our tank truck hoses deliver consistent performance in the harshest operating conditions, from arctic cold to desert heat.

Extended Service Life

Advanced materials and manufacturing composite hose processes result in exceptional durability. Multiple reinforcement layers and chemical-resistant linings ensure long-term reliability, reducing replacement frequency and total cost of ownership.

Operational Efficiency

Lightweight tank truck hose construction combined with excellent flexibility makes handling easier and speeds up loading operations. Smooth inner surface ensures optimal flow rates, maximizing throughput at busy terminals.

Custom Solutions Available

We offer customization options including specific lengths, end fittings, and pressure ratings to meet your exact operational requirements. Our technical team works with you to specify the optimal tank truck hose solution.

Years of Industry Experience

Satisfied Customers Worldwide

Technical Support Available

Installation & Maintenance Guidelines

Installation Best Practices

Proper Fitting Selection

Always use compatible end fittings designed for composite hose applications. Ensure fittings match the hose diameter and pressure rating specifications.

Avoid Excessive Bending

Never bend the tank truck hose beyond its minimum bend radius specification. Excessive bending can damage internal wire structure and compromise integrity.

Electrical Continuity

Verify electrical continuity between composite hose ends before operation. Proper grounding is essential for safe petroleum transfer and static dissipation.

Storage Recommendations

Store tank truck hoses in a cool, dry location away from direct sunlight. Avoid contact with sharp objects and chemicals that may degrade the outer cover.

Maintenance & Inspection

Regular Visual Inspection

Conduct daily visual inspections for signs of wear, bulging, kinking, or outer cover damage. Address any abnormalities immediately to prevent failures.

Pressure Testing

Perform periodic pressure tests according to industry standards and local regulations. Document all test results for maintenance records.

Cleaning Procedures

Clean composite hoses regularly using appropriate cleaning agents compatible with petroleum products. Ensure complete drainage after cleaning before storage.

Replacement Schedule

Follow manufacturer recommendations for service life and replacement intervals. Replace hoses showing signs of degradation regardless of age.

Frequently Asked Questions

What is the typical service life of these composite hoses?

With proper maintenance and handling, our composite hoses typically provide reliable service for three to five years. Service life depends on usage frequency, product type, operating conditions, and adherence to maintenance schedules. Regular inspections and proper storage significantly extend hose longevity.

Can these composite hoses handle other chemicals besides petroleum products?

These hoses are specifically designed and optimized for petroleum products including gasoline, diesel, kerosene, and jet fuel. For other chemicals, please contact our technical team to discuss compatibility and recommend the appropriate hose construction for your specific application requirements.

What certifications do your composite hoses comply with?

Our composite hoses are manufactured according to international standards for petroleum handling equipment. They meet requirements for static conductivity, pressure ratings, and chemical compatibility. Specific certification documentation can be provided upon request to meet your facility's compliance requirements.

What fitting options are available?

We offer a comprehensive range of end fittings including camlock couplings, flanges, threaded connections, and custom configurations. Fittings are available in various materials including stainless steel, aluminum, and brass. Our technical team can recommend the optimal fitting type for your specific application and compatibility requirements.

Do you offer custom lengths beyond the standard 40 meters?

Yes, we can manufacture custom lengths to meet your operational needs. While standard lengths are optimized for most applications, we understand that specific installations may require different dimensions. Contact us with your requirements, and we'll provide a customized solution with appropriate lead times.

What warranty do you provide?

We stand behind our product quality with a comprehensive warranty covering manufacturing defects. Warranty terms vary based on application and operating conditions. We also provide technical support throughout the product lifecycle to ensure optimal performance and address any concerns promptly.

Quality Assurance Process

Raw Material Inspection

Every composite hose component verified for quality and specifications

Manufacturing Control

Continuous monitoring during tank truck hose production process

Pressure Testing

Hydrostatic testing at specified pressure levels

Final Inspection

Comprehensive quality check before shipment

Ready to Enhance Your Operations?

Contact our technical team today to discuss your specific requirements and receive expert guidance on selecting the optimal composite hose solution for your tank truck or dock loading operations.

GET A QUOTEPremium composite hoses engineered for reliability in demanding petroleum transfer applications

Trusted by leading oil terminals, refineries, and transportation companies worldwide

feedback Report comment