British Bsp Hydraulic Fittings

Evergood specifically design our hydraulic fittings—which use the BSP (British Standard Pipe) threading standard—to guarantee maximum reliability and adhere to the highest criteria for quality across the sector.

What is BSP Hydraulic Fittings

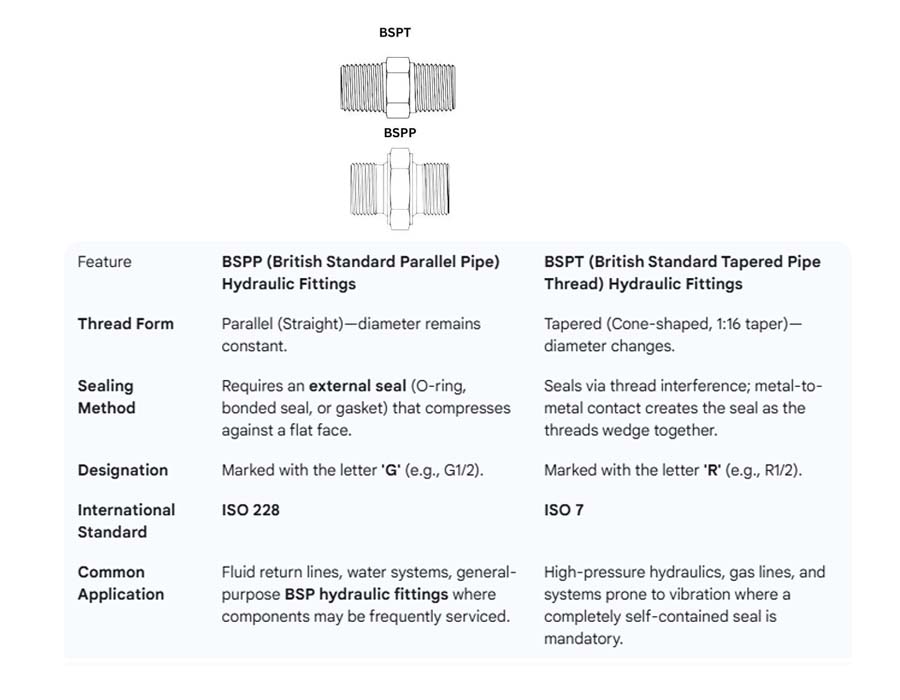

BSP hydraulic fittings are a cornerstone in fluid power systems, particularly in Europe, Australia, and many Commonwealth nations. Standing for British Standard Pipe, this standard defines a comprehensive set of screw threads for connecting and sealing pipes and hydraulic fittings. Understanding the two distinct types—BSPP (Parallel) and BSPT (Tapered)—is crucial for ensuring secure, leak-proof connections in any system that relies on British hydraulic fittings.

Two Core Types: BSPP vs. BSPT

All BSP threads feature a 55-degree flank angle (Whitworth thread form), but their geometry and sealing mechanisms are entirely different:

Two Sealing Mechanisms for BSP Hydraulic Fittings

The method of sealing is the most critical difference between the two BSP hydraulic fittings types.

BSPP Sealing (Parallel)

BSPP hydraulic fittings rely on a mechanical seal rather than thread deformation. The parallel threads simplify assembly and are ideal for systems that require frequent disconnection.

Bonded Seals: Consist of a rubber gasket bonded to a metal ring. When tightened, the flat face of the BSPP hydraulic fitting compresses the seal, creating a highly reliable, leak-proof barrier.

O-Rings: Elastomeric O-rings fit into grooves and are compressed to form a static seal. This method is effective across a range of applications.

BSPT Sealing (Tapered)

BSPT hydraulic fittings are self-sealing. As the threads are tightened, the metal of the tapered male thread forces into the root of the female thread, deforming slightly and forming a secure, high-pressure seal. While the tapered threads can seal on their own, a thread sealant (like PTFE tape) is often recommended to fill minor gaps and ensure gas-tight security, especially in critical applications.

Key Benefits and Applications of British Hydraulic Fittings

The versatility and robust nature of British hydraulic fittings make them indispensable in several industries:

Versatility and Durability: BSP hydraulic fittings are manufactured from materials like carbon steel, stainless steel, and brass, offering exceptional durability and resistance to wear and high pressure. This makes them a cost-effective choice due to their longevity and low maintenance.

Wide Range of Uses: These BSP hydraulic fittings are globally trusted for various applications, including:

Industrial Hydraulic Systems (excavators, presses).

Gas Piping and High-Pressure Lines.

Water Supply and General Fluid Transfer

Marine Applications, where corrosion resistance is essential.

To conclude, mastery of BSP hydraulic fittings is essential for any professional working with hydraulic systems. This guide clarifies the distinct features of BSPP hydraulic fittings and BSPT hydraulic fittings, emphasizing that a secure connection is achieved only through correct thread identification and the application of the appropriate ISO-compliant sealing method. Use this knowledge to build systems that are efficient, safe, and built to last.

feedback Report comment