This air hose buying guide explores essential pneumatic hose materials (Poly, Rubber,Hybrid, PVC), diameters, and...

Air Hose Buyer’s Guide: Selecting the Best Pneumatic Hose

Air Hose Introduction

When it comes to pneumatic tools, most people focus on the compressor itself—its horsepower, CFM output, and price tag. But there's a critical component that often gets overlooked: the air hose. Your air hose is the lifeline between your compressor and your tools, and choosing the wrong one can result in poor performance, tool failure, or even safety hazards.

Whether you're a professional contractor working on multiple job sites daily, a dedicated DIYer tackling weekend projects, or a shop owner investing in pneumatic equipment, selecting the right air hose impacts your productivity, tool longevity, and bottom line. This comprehensive guide breaks down everything you need to know to make an informed decision.

Why Your Air Hose Choice Matters

Before diving into specifications, let's understand why this seemingly simple accessory deserves serious consideration. Your air hose isn't just a delivery mechanism—it directly affects:

Performance: Friction inside the hose causes pressure drops. A 100-foot 1/4-inch air hose can lose 3-8 psi depending on flow rate, potentially preventing your tool from operating at full capacity.

Tool Reliability: Inadequate air pressure causes tools to bind, overheat, and fail prematurely. The right hose maintains consistent pressure delivery.

Cost Efficiency: A quality hose lasts longer, requires fewer replacements, and minimizes downtime on the job site.

Safety: Hose failures under pressure can cause injuries. Choosing materials rated for your working conditions is essential.

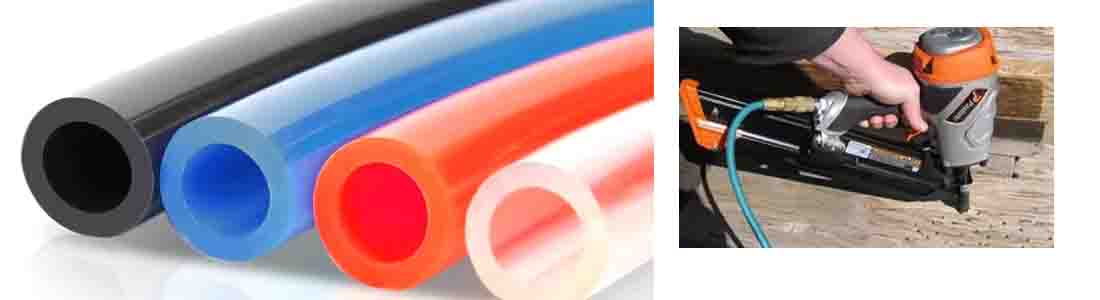

Complete Hose Material Breakdown

Polyurethane (Poly) Hose: The Versatile Workhorse

Polyurethane hose has become increasingly popular, and for good reason. This single-material construction offers an impressive balance of properties that work well in most applications.

- Key Characteristics:

- Weighs 30-40% less than hybrid alternatives

- Maintains flexibility in temperature ranges from -40°F to 140°F

- Resists UV degradation better than PVC

- Excellent for outdoor job sites

- Easy to coil and store

Best For: General construction, outdoor work, roofing, carpentry, and mobile contractors who move equipment frequently.

Price Point: Mid-range; typically 20-30% less expensive than hybrid but more costly than PVC.

Durability: 5-7 years with proper maintenance under normal conditions.

Hybrid Air Hose: The Premium Choice

Hybrid air hoses combine polyurethane, PVC, and rubber in a layered construction, creating a hose that performs exceptionally well in challenging environments.

Key Characteristics:

- Superior flexibility, even in sub-zero temperatures (-58°F and below)

- Kink-resistant design prevents tangles and saves setup time

- Oil and ozone resistant

- Higher pressure ratings available

Best For: Cold-weather work, industrial applications, automotive shops, environments with chemical exposure, and professionals who demand premium reliability.

Price Point: Premium; 40-60% more expensive than PVC alternatives.

Durability: 8-10+ years; best long-term value despite higher initial cost.

PVC Air Hose: The Budget-Friendly Option

PVC hose serves a specific market segment and performs well within its parameters.

Key Characteristics:

- Most economical option available

- Suitable for warm weather (40°F to 100°F)

- Lightweight compared to rubber

- Easy to maneuver around obstacles

- Good for stationary installations

Best For: Garage setups, warm climates, budget-conscious DIYers, indoor workshops, temporary installations.

Price Point: Budget-friendly; lowest cost per foot.

Durability: 3-5 years; shorter lifespan due to material degradation in UV exposure.

Limitation: Becomes rigid in cold weather, making it difficult to work with below 40°F.

Rubber Air Hose: The Heavy-Duty Legacy Option

Traditional rubber air hoses remain available, though less common in modern applications.

Characteristics:

- Extremely durable and puncture-resistant

- Excellent high-pressure tolerance

- Heavy (significant weight penalty)

- Limited flexibility compared to PVC

Best For: Industrial settings where equipment stays stationary, high-pressure applications, and shops where durability outweighs portability concerns.

Nylon Recoil Air Hose: Compact Storage Solutions

Self-coiling nylon hoses offer unique advantages in specific applications.

Characteristics:

- Automatic retracting design saves storage space

- Compact and tidy appearance

- Excellent for controlled shop environments

- Limited to moderate pressure applications

Best For: Automotive shops, tire shops, detail centers, and controlled indoor environments.

Note: Not recommended for outdoor or cold-weather use.

Environmental Factors

| Material | Cold Flexibility | Heat Resistance | UV Resistance | Abrasion Resistance | Best Environment |

| PVC | Poor (Brittle) | Moderate | Low | Moderate | Indoor / Basic use |

| Polyurethane (PU) | Excellent | Good | High | Superior | High-friction / Roofing |

| Hybrid | Excellent | Good | High | Good | Professional / All-weather |

| Rubber | Good | Excellent | Moderate | High | Heavy-duty / Industrial |

| Nylon | Moderate | High | Moderate | High | Fixed lines / Robotic |

Length Selection: Finding Your Perfect Distance

Choosing the right hose length is a balance between convenience and efficiency.

Standard Lengths and Applications

50-Foot Hoses: Ideal for compact job sites, tight working quarters, or when your compressor sits close to your work area. A 50-footer minimizes pressure drop and friction loss—critical when your tool's CFM requirement approaches your compressor's output.

100-Foot Hoses: The industry standard for most professionals. This length provides maximum flexibility in equipment placement and can eliminate the need for extension cords, which strain electric motors. The longer reach means you can position your compressor in a safer, more sheltered location.

Calculating Your Required Length:

Don't simply guess. Measure the actual path from your compressor location to your farthest working point, accounting for obstacles and necessary slack. Add 10-15 feet for safety margin and coiling space. Remember that a coiled hose develops pressure hotspots, so allow extra length for proper laying.

Pressure Drop Considerations

Friction loss increases dramatically with hose length. Here's what to expect:

- 50-foot 1/4-inch air hose: 2-4 psi loss at 20 CFM

- 100-foot 1/4-inch hose: 5-8 psi loss at 20 CFM

- 100-foot 3/8-inch air hose: 1-3 psi loss at 20 CFM

If your tool requires 90 psi to operate properly and you're running 100 feet of 1/4-inch hose, you need a compressor capable of delivering 100+ psi. This is why wider-diameter hoses become critical for longer distances.

Inside Diameter: Understanding the Impact

For Example, 1/4-Inch Diameter air hose : Lightweight & Portable

- Best For: DIYers, finishing work (nail guns, airbrushes), and distances under 50 feet.

- Pros: 40% lighter and more compact than 3/8" hoses; easiest to coil and store; lower cost.

- Cons: High friction loss over distance; cannot support high-CFM tools (grinders/impact wrenches).

3/8-Inch Diameter air hose : High Performance & Reach

- Best For: Professional contractors, industrial use, high-CFM tools, and runs exceeding 50 feet.

- Pros: Reduces friction loss by up to 75%; maintains steady pressure over 100+ feet; ideal for continuous-use tools like sanders.

- Cons: 40% heavier; more difficult to maneuver; higher initial investment for hose and fittings.

Hybrid Sizing Strategy

Smart contractors often use both sizes. A 3/8-inch main line carries air from the compressor to the work area, with 25-50 feet of 1/4-inch branch hoses for individual tools. This approach minimizes pressure drop while keeping tool-side hoses manageable.

Working Pressure Ratings: Safety First

Every hose has a maximum working pressure rating, and exceeding this rating creates safety hazards.

Common Pressure Ratings:

- Light-duty Air hoses: 100-150 psi

- Standard hoses: 200-250 psi

- Heavy-duty hoses: 300+ psi

Your Safety Rule: Choose a hose rated for at least 1.5 times your compressor's maximum pressure output. If your compressor tops out at 150 psi, use hoses rated for 225 psi minimum. This safety margin accounts for pressure spikes and transient conditions.

Most pneumatic tools operate between 80-90 psi, so standard 250-psi rated hoses provide ample safety margin for typical applications.

Additional Features Worth Considering

Couplers and Fittings

Quality couplers matter. Brass couplers resist corrosion better than steel. Quick-disconnect couplers save time when switching between tools or locations. Flat-face couplers prevent air loss and pressure fluctuations when disconnecting.

Protective Covers

Spiral-wrapped or mesh-reinforced outer covers protect against abrasion and UV damage, extending hose life in harsh environments.

Color Coding

Colored bands or stripes help identify hose size and type, reducing confusion on large job sites and improving safety protocol compliance.

Practical Selection Scenarios

| User Category | Recommended Material | Common Specifications | Core Advantages |

| Home / DIY User | PVC | 1/4" ID, 50ft | Budget-friendly, ideal for light-duty tools |

| Professional Contractor | Hybrid/Rubber | 3/8" ID, 100ft | All-weather use, kink-resistant, durable |

| Fixed Shop / Factory | Rubber or PU | 3/8" ID, High Pressure | High abrasion resistance, built for high-frequency use |

Maintenance and Care Tips

Extend your hose investment through proper maintenance:

Storage: Coil loosely in a shaded area away from direct sunlight and heat sources. Tight coils can develop permanent kinks.

Inspection: Check monthly for cracks, splits, bulges, or leaks. A small crack develops into a failure within weeks under pressure.

Cleaning: Remove dirt and moisture after use. Moisture inside the hose promotes corrosion and tool damage.

Pressure Testing: Have hoses professionally tested annually if used in industrial settings or continuously under high pressure.

Replacement: Even the best hoses have lifespans. Replace every 5-7 years for light use, every 3-5 years for heavy use, regardless of apparent condition.

Conclusion

Selecting the right air hose is critical to tool performance, safety, and productivity. The right choice reduces downtime, extends equipment life, and keeps job sites running smoothly.

Focus first on material suited to your environment, then choose the correct length and diameter based on your tools’ CFM needs. While premium hoses cost more upfront, their durability and reliability deliver long-term value.

Whether upgrading or equipping a new shop, matching real working conditions with proper specifications ensures consistent performance year after year.

Leave a comment

Comments

-

Air Hose Buyer’s Guide

By: Adalira On 01/20/2026This air hose buyer's guide was incredibly helpful! I finally understand the difference between PVC and rubber air hoses. Thanks to Evergood's detailed breakdown of PSI and temperature ratings, I purchased the perfect pneumatic hose for my factory. The durability is outstanding!

Latest comments