This air hose buying guide explores essential pneumatic hose materials (Poly, Rubber,Hybrid, PVC), diameters, and...

Ocean's Lifelines: The Complete Guide to Petroleum Hoses in the Marine Industry

Introduction-Importance of Marine Petroleum Hose

The maritime industry depends on specialized fluid transfer systems for safe and efficient vessel operations. Petroleum hose assemblies form the backbone of fuel delivery, storage management, and transfer operations, whether facilitating ship-to-shore transfers or managing onboard fuel systems. The selection and maintenance of appropriate marine hose solutions directly impact operational safety, environmental protection, and cost efficiency.

The demanding marine environment presents unique challenges that distinguish nautical applications from land-based settings. Constant exposure to saltwater, extreme temperature fluctuations, UV radiation, and mechanical stress from wave action require hoses engineered with superior materials and construction. This guide examines essential aspects of rubber petroleum hoses designed for maritime service, providing technical insights for marine engineers, vessel operators, and maintenance professionals.

Petroleum Hose Classification and Applications

Primary Functional Categories

Petroleum transfer hose systems are engineered for moving refined petroleum products between vessels, storage facilities, and shore installations. These hoses must withstand significant pressure variations while maintaining flexibility during transfer operations. Modern petroleum transfer hose designs incorporate multi-layer construction with specialized compounds that resist aromatic hydrocarbons while providing mechanical durability.

Fuel delivery systems aboard vessels utilize dedicated petroleum hose assemblies connecting storage tanks to engines, generators, and auxiliary equipment. These internal distribution networks require sustained pressure resistance and compatibility with various fuel grades including diesel, heavy fuel oil, and marine gas oil.

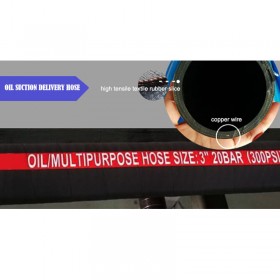

Petroleum suction hose configurations serve critical roles in tank cleaning and bilge management. Unlike pressure hoses, petroleum suction hose assemblies must maintain structural integrity under vacuum conditions while resisting collapse. Reinforcement in suction applications typically employs rigid spiral wire construction rather than textile braiding.

Dock hose assemblies bridge connections between shore infrastructure and vessel manifolds during loading and unloading operations. Dock hose systems face unique challenges including tidal variations, vessel movement, and rapid deployment requirements. These hoses often feature larger diameters and enhanced abrasion resistance compared to shipboard installations.

Specialized Marine Applications

Marine hose technology extends beyond simple fuel transfer to diverse petroleum handling scenarios. Offshore bunkering operations utilize floating marine hose strings extending hundreds of meters, incorporating specialized buoyancy sections and articulated joints. These configurations enable fuel transfer in open water where traditional shore connections prove impractical.

Ballast and cargo operations on tanker vessels employ dedicated petroleum hose systems for managing product segregation and transfer sequences. Chemical tankers may operate dozens of independent hose circuits, each rated for specific product compatibility and pressure ranges.

Petroleum tank truck hose assemblies, while primarily designed for land operations, find application in maritime contexts during emergency refueling or when vessels access facilities lacking dedicated marine infrastructure. Understanding petroleum tank truck hose limitations becomes essential when evaluating suitability for temporary marine service.

Petroleum Hose Rubber Material Selection

Performance Characteristics

Reliable marine hose performance depends on elastomer compounds engineered for simultaneous resistance to petroleum products, marine environmental exposure, and mechanical stresses. Nitrile rubber (NBR) dominates petroleum hose applications due to exceptional resistance to aliphatic hydrocarbons and favorable cost-performance ratios. Modern NBR formulations for petroleum transfer hose service incorporate varying acrylonitrile content, with higher percentages providing enhanced fuel resistance at the expense of low-temperature flexibility.

Fluoroelastomer (FKM) compounds represent premium solutions for demanding petroleum hose applications involving high temperatures, aggressive aromatics, or extended service intervals. FKM-lined hoses maintain integrity when handling gasoline, aviation fuel, and other light petroleum fractions. Superior thermal stability extends operational temperature ranges to 150°C, essential for engine compartment installations and hot oil service.

Chloroprene rubber (CR) offers balanced properties particularly valued in dock hose construction where resistance to weathering, ozone, and abrasion takes priority. The flame resistance of polychloroprene provides additional safety margins in marine applications. However, chloroprene exhibits limited resistance to aromatic petroleum fractions, restricting use to specific fuel types.

Material Compatibility

Selecting appropriate compounds for petroleum hose assemblies requires analyzing transported fluid chemistry. Aromatic content, sulfur concentration, and additive packages in marine fuels significantly influence material degradation rates. Modern low-sulfur fuels present new challenges, as reduced sulfur content alters lubricity characteristics and may increase microbial contamination risks.

Temperature parameters critically influence material selection for petroleum transfer hose systems. Arctic operations demand compounds maintaining flexibility below -40°C, while tropical climates and engine rooms require materials withstanding continuous exposure above 80°C. Thermal cycling during loading and discharge operations further stresses hose materials, potentially accelerating deterioration.

Marine hose compounds must resist petroleum products and marine contaminants including saltwater, biological growth, and atmospheric pollutants. UV stabilizers protect external layers from photodegradation during deck storage. Antioxidants and antiozonants extend service life by mitigating environmental attack mechanisms.

Structural Design

Multi-Layer Construction

Professional-grade petroleum hose assemblies employ sophisticated multi-layer designs distributing mechanical loads while maintaining chemical resistance. The innermost tube contacts petroleum products directly, requiring optimal fuel compatibility and smooth bore finishes. Modern petroleum transfer hose tubes incorporate conductive carbon black dispersion to dissipate static electricity, preventing ignition risks.

Reinforcement layers constitute the strength backbone, with specifications varying according to pressure ratings and flexibility requirements. High-pressure petroleum suction hose assemblies typically employ multiple textile braids of synthetic fiber such as polyester or aramid. Spiral-wound steel wire reinforcement offers maximum collapse resistance for suction applications.

The outer cover protects reinforcement from environmental degradation while providing abrasion resistance. Dock hose covers must withstand constant chafing against bollards, dock edges, and vessel hulls. Color-coding facilitates product identification and inspection, with standardized schemes indicating service ratings across different petroleum products.

Marine Hose End Fitting Engineering

Connection integrity represents a critical vulnerability, as improper end fitting attachment causes most service failures. Modern petroleum transfer hose assemblies utilize ferrule-crimped attachments that mechanically lock hose layers through controlled deformation. Proper crimping ensures uniform pressure distribution and prevents internal tube pull-out.

Flange connections dominate large-diameter marine hose installations, providing robust sealing through bolted joint faces. Marine-grade flanges incorporate corrosion-resistant materials including stainless steel or aluminum bronze alloys. Gasket selection must account for petroleum product compatibility and aggressive marine environments.

Quick-connect couplings streamline petroleum tank truck hose and temporary transfer operations by enabling rapid connection without tools. Cam-lock and dry-break designs prevent spillage during connection sequences while ensuring positive locking under pressure.

Marine Prteoleum Hose Standards and Certification

Regulatory Framework

Marine hose assemblies operating internationally must comply with International Maritime Organization (IMO) standards. The SOLAS convention mandates fire safety standards impacting petroleum hose specifications aboard commercial vessels. These regulations influence material flammability ratings, routing restrictions, and emergency shutdown systems.

Classification society rules from Lloyd's Register, Det Norske Veritas, and American Bureau of Shipping provide detailed technical specifications for petroleum transfer hose installations. These standards address material properties, pressure testing protocols, installation practices, and inspection intervals.

The Oil Companies International Marine Forum (OCIMF) publishes guidelines specifically addressing dock hose systems in tanker operations. Major oil companies often require OCIMF compliance as a condition for accepting vessels at their terminals.

Testing Protocols

Rigorous testing validates petroleum hose performance before service release and throughout operational life. Hydrostatic pressure testing subjects assemblies to pressures typically 1.5 to 2 times rated working pressure. Marine hose assemblies undergo pressure testing during initial production and at prescribed service intervals.

Electrical continuity testing ensures proper grounding of conductive petroleum transfer hose assemblies, verifying resistance between end fittings falls within specified limits (typically less than 10 ohms per meter). This prevents static electricity accumulation that could trigger explosions when handling volatile petroleum products.

Compatibility testing simulates long-term exposure of hose materials to specific petroleum products under controlled conditions. These accelerated aging protocols predict service life by measuring changes in tensile strength, elongation, and volume swell. Petroleum suction hose products additionally undergo vacuum testing to ensure collapse resistance.

Installation Best Practices

Proper Routing and Support

Correct installation techniques fundamentally determine petroleum hose service life and reliability. Hose routing must respect minimum bend radius specifications, typically 10 to 20 times hose diameter depending on reinforcement construction. Excessive bending concentrates stress in reinforcement layers, potentially causing premature failure through wire fatigue or textile separation.

Support spacing guidelines prevent sagging and excessive movement that accelerates wear at connection points. Marine hose installations generally require support intervals not exceeding 1 to 2 meters for horizontal runs, with closer spacing for vertical configurations. Support hardware should incorporate cushioning materials that prevent chafing while allowing thermal expansion.

Twisting represents a particularly damaging installation error that compromises petroleum hose structural integrity. During installation, technicians must ensure assemblies remain in their natural lay without torsional stress. Dock hose handling procedures should incorporate rotation awareness to prevent accumulated twist during repeated deployment cycles.

Connection Procedures

Proper gasket installation and bolt tightening sequences ensure reliable sealing at petroleum transfer hose flanged connections. Gaskets must be correctly sized and centered, with material selection appropriate for both petroleum product and service temperature. Bolts should be tightened in star patterns using calibrated torque wrenches to achieve uniform compression.

Marine hose quick-connect couplings require careful engagement to ensure full locking and proper gasket seating. Operators should verify coupling security through visual inspection of locking mechanisms and gentle pull testing before pressurizing systems.

Pressure testing before placing petroleum hose systems into service identifies installation defects and verifies system integrity. Initial pressurization should occur gradually while personnel inspect all connections for weeping or leakage.

Maintenance and Inspection

Routine Inspection

Systematic inspection programs form the foundation of reliable petroleum hose operation. Visual examinations should occur at regular intervals based on service conditions, typically monthly for critical transfer systems and quarterly for auxiliary circuits. Inspectors examine cover conditions for cracks, blisters, abrasion damage, and petroleum contamination. Petroleum transfer hose assemblies showing cover deterioration require detailed assessment.

End fitting inspection focuses on corrosion, mechanical damage, and leakage signs at crimp or clamp interfaces. Ferrule slippage indicates improper crimping or overtension, requiring immediate hose retirement. Dock hose assemblies face particularly severe impact damage and abrasion exposure, demanding more frequent thorough inspection.

Internal inspection of petroleum suction hose assemblies requires periodic removal for bore examination. Deposits, contamination, or liner deterioration may compromise flow capacity and product quality. Specialized borescope equipment enables inspection without complete disassembly.

Functional Testing

Pressure testing at prescribed intervals validates ongoing marine hose integrity throughout service life. International maritime regulations and classification society rules specify testing frequencies, typically annually for critical petroleum transfer systems. Test pressures generally equal 1.5 times maximum working pressure.

Electrical conductivity testing of petroleum transfer hose assemblies ensures continued effectiveness of static dissipation properties. Over time, environmental exposure and contamination may increase electrical resistance above safe limits. Simple continuity meters verify end-to-end resistance remains below specified values.

Flow testing identifies restrictions in petroleum hose systems caused by internal deposits, liner swelling, or mechanical deformation. Measuring pressure drop at known flow rates and comparing against baseline performance reveals degradation requiring investigation.

Service Life and Replacement

Establishing petroleum hose service life limits requires balancing safety against economic factors. Manufacturers typically provide recommended service life guidance ranging from 5 to 10 years depending on application severity. However, actual service conditions may justify shortened or extended intervals based on inspection findings.

Age-related deterioration affects marine hose assemblies even when visual appearance remains satisfactory. Rubber compounds gradually lose elasticity through oxidation and thermal aging that compromise flexibility and strength. Dock hose systems in severe service may warrant replacement after 3-5 years despite passing visual inspections.

Damage assessment determines whether petroleum transfer hose repairs prove feasible or replacement becomes necessary. Surface cover damage not penetrating reinforcement layers may be acceptable depending on extent and location. However, any damage exposing reinforcement mandates replacement. Bulging, soft spots, or internal liner separation require immediate retirement regardless of age.

Petroleum Delivery HoseTroubleshooting Common Issues

Leak Diagnosis

Petroleum hose leakage manifests in various forms requiring different diagnostic approaches. Weeping at flanged connections often results from improper installation, gasket degradation, or flange distortion. Remedy typically involves disassembly, inspection, and reassembly with new gaskets using proper torque procedures.

Leakage from the hose body indicates serious deterioration demanding immediate replacement. Cover cracks allowing petroleum seepage signal advanced degradation that has compromised internal layers. Marine hose assemblies showing body leakage present fire and environmental risks requiring immediate service isolation.

Petroleum suction hose leakage during vacuum service may result from liner separation or perforation not evident during pressure operations. Vacuum conditions pull outside air through tiny defects, causing performance issues and potential contamination.

Flow Restrictions

Reduced flow capacity in petroleum transfer hose systems may stem from multiple causes requiring systematic investigation. Internal deposits from petroleum residues restrict bore area and increase friction losses. Chemical cleaning using compatible solvents may restore flow capacity if deposits haven't permanently damaged liner materials.

Liner swelling from chemical incompatibility reduces effective bore diameter in petroleum hose assemblies. This phenomenon typically develops gradually as elastomer compounds absorb aromatic fractions or incompatible fuel components. Once liner swelling occurs, removal from service becomes necessary as the condition proves irreversible.

External compression from improper clamping or routing restrictions may collapse petroleum suction hose assemblies, limiting flow capacity. Physical inspection while operating under vacuum conditions may reveal collapse not apparent when depressurized.

Marine Petroleum Hose Conclusion

The critical role of marine hose systems in petroleum handling operations demands professional attention to specification, installation, maintenance, and troubleshooting. Success requires understanding the unique challenges of the marine environment and selecting petroleum hose solutions engineered specifically for nautical service.

Material science advances continue improving petroleum transfer hose capabilities, with new elastomer formulations and construction techniques extending service life while reducing environmental impact. However, technological improvements cannot compensate for improper installation practices or inadequate maintenance programs.

Regulatory compliance represents both a legal obligation and a practical framework for safe operations. International standards governing petroleum hose specifications and testing protocols reflect decades of industry experience. Adhering to these requirements provides reasonable assurance of safe, reliable performance while facilitating international vessel operations.

Economic considerations should balance initial equipment costs against total lifecycle expenses including maintenance, testing, downtime, and environmental risk. Premium marine hose products with superior materials typically justify higher purchase prices through extended service intervals and improved reliability. The costs associated with petroleum spills, vessel delays, or system failures dwarf the incremental expense of quality components properly maintained throughout their service life.

Evergood is a well-established and experienced manufacturer industrial hose, with a distinct focus on the Oil and Gas industry. Evergood produce a range of specialized hoses designed for demanding petroleum applications, including Diesel Fuel Delivery Hoses and various Oil Suction Discharge Hoses with high-pressure ratings. These hoses are engineered for superior resistance to petroleum and blended hydrocarbon products, often with an aromatic content of up to 50%. Their deep experience in manufacturing high-quality, durable hoses that resist air blisters, porosity, and splits—along with securing certifications like ISO, MSHA, and CE—underscores their competence and reliability as a supplier for the strenuous needs of the oil and gas sector. Any help, contact us.

Leave a comment

Comments

-

a great deep dive into petroleum hoses

By: Salvatora On 01/27/2026Ocean's Lifelines" is a fantastic read! It’s a great deep dive into how essential petroleum hoses are for marine safety and efficiency. This guide makes a complex topic super easy to understand. Thanks for sharing these expert insights!

Latest comments