This air hose buying guide explores essential pneumatic hose materials (Poly, Rubber,Hybrid, PVC), diameters, and...

Stop Sucking Air: Choosing the right rubber Suction Hose That Eliminates Vacuum

Introduction: The Hidden Infrastructure of Fluid Transfer-water suction hose

Picture a construction site at dawn. Water has accumulated overnight in a foundation excavation, threatening to delay the entire project schedule. A powerful pump roars to life, but the real hero of this operation remains largely invisible—a robust rubber water suction hose that must withstand negative pressure, resist abrasion from debris, and maintain structural integrity under demanding conditions. This seemingly simple component represents a sophisticated convergence of material science, mechanical engineering, and decades of industrial innovation.

n industries ranging from agriculture to mining, from emergency response to municipal infrastructure, the reliability of fluid transfer systems depends fundamentally on one critical element: the quality and appropriate selection of rubber water suction hose. Unlike discharge hoses that simply convey pressurized fluids, suction applications present unique engineering challenges that demand careful consideration of materials, construction methods, and operational parameters.

This exploration delves into the technical sophistication behind these essential industrial components, examining the material science that determines performance, the critical parameters that guide proper selection, and the installation practices that ensure long-term reliability. Understanding these elements transforms what appears to be a commodity purchase into a strategic engineering decision with significant operational and financial implications.

The Science Behind Performance: Wter Hose Material Selection and Properties

The performance envelope of any rubber water suction hose begins with fundamental material choices. This decision tree involves balancing multiple, often competing properties: flexibility versus durability, chemical resistance versus cost-effectiveness, temperature range versus manufacturing complexity. The material science behind rubber suction hose construction represents one of the most critical factors determining field performance and service life.

Natural Rubber: The Traditional Standard

Natural rubber has served as the foundation material for reinforced suction hose manufacturing for over a century, and for compelling technical reasons. Its exceptional tear resistance and superior flexibility at low temperatures make natural rubber ideal for applications requiring frequent handling and deployment. The molecular structure of natural rubber provides outstanding resilience—the ability to return to original dimensions after deformation—which proves essential when a pump suction hose repeatedly experiences vacuum cycles.

The elastic memory of natural rubber means that when negative pressure attempts to collapse the hose wall, the material actively resists deformation and recovers completely once pressure normalizes. This characteristic becomes particularly valuable in intermittent pumping operations where the hose experiences repeated stress cycles. Agricultural irrigation systems, for example, benefit tremendously from natural rubber's fatigue resistance during seasonal operations involving thousands of pump cycles.

However, natural rubber presents limitations that must be acknowledged. Its vulnerability to ozone degradation, petroleum products, and prolonged UV exposure restricts its application in certain industrial environments. A natural rubber-based rubber water suction hose stored improperly or exposed to ozone-generating equipment may develop surface cracking within months, compromising structural integrity long before normal wear would dictate replacement.

Synthetic Alternatives: Engineered Performance

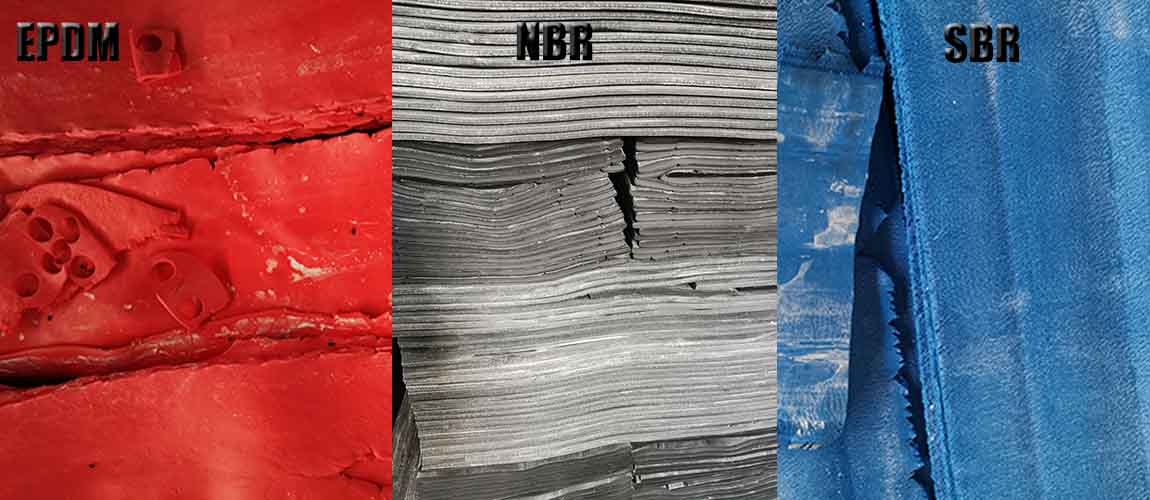

Modern synthetic rubbers emerged from the need to overcome natural rubber's limitations while potentially offering enhanced properties for specific applications. Styrene-Butadiene Rubber (SBR) represents the most common synthetic alternative in rubber suction hose manufacturing, offering improved abrasion resistance and better aging characteristics than natural rubber at a competitive price point.

SBR-based rubber water suction hose demonstrates superior performance in applications involving abrasive materials. Mining dewatering operations, where suspended solids constantly scour the internal surface, benefit from SBR's harder compound formulation. Laboratory testing consistently shows SBR compounds maintaining wall thickness longer than comparable natural rubber when exposed to abrasive slurries, translating directly to extended service intervals in demanding field conditions.

Ethylene Propylene Diene Monomer (EPDM) rubber brings exceptional weather resistance and thermal stability to reinforced suction hose applications. EPDM maintains flexibility across an impressive temperature range—typically from -40°F to +212°F—making it ideal for extreme climate operations. Municipal water departments in northern regions increasingly specify EPDM-based pump suction hose for emergency response equipment that must perform reliably whether stored in summer heat or deployed during winter flooding.

The chemical resistance profile of EPDM also deserves attention. While not suitable for petroleum products, EPDM demonstrates excellent resistance to alkaline solutions, making it appropriate for certain industrial applications where pH variations occur. Wastewater treatment facilities often prefer EPDM rubber suction hose when handling process streams with elevated pH levels that would degrade natural rubber compounds.

Nitrile rubber (NBR) addresses the petroleum resistance gap inherent in natural rubber and EPDM. Applications involving fuel transfer, oil-contaminated water, or hydrocarbon exposure demand NBR's resistance to swelling and degradation. While less common in general-purpose water applications, NBR-based rubber water suction hose fills an essential niche in industrial facilities where incidental fuel contact may occur.

Compound Formulation: Beyond Base Polymer

The base polymer—whether natural or synthetic—represents only the starting point in rubber compound development. Modern rubber water suction hose manufacturers employ sophisticated compound formulations incorporating carbon black for reinforcement, antioxidants for aging resistance, plasticizers for flexibility, and curing agents to develop the final material properties.

Carbon black loading significantly impacts abrasion resistance and material strength. Higher carbon black content creates a harder, more wear-resistant compound but reduces flexibility. Heavy duty suction hoses designed for abrasive service typically employ higher carbon black levels, accepting reduced flexibility as a reasonable tradeoff for extended wear life. Conversely, soft suction hose formulations prioritize flexibility for applications requiring tight coiling or complex routing, using lower carbon black content despite slightly reduced abrasion resistance.

The art of compound formulation involves optimizing this complex matrix of properties for specific application profiles. A rubber suction hose intended for agricultural irrigation differs substantially in compound formulation from one designed for mining slurry, even if both utilize the same base polymer. Understanding these distinctions helps explain performance variations between products that appear superficially similar but deliver markedly different field results.

Critical Selection Water Suction Hose Parameters: Engineering the Right Match

Proper selection of a rubber water suction hose involves systematic evaluation of multiple operational parameters. This decision matrix determines whether the hose will deliver reliable long-term service or become a recurring maintenance problem compromising system efficiency and generating unexpected costs.

Inside Diameter: The Foundation of Flow Efficiency

Inside diameter selection represents the most fundamental parameter, directly governing flow capacity and system efficiency. The relationship between diameter and flow follows well-established fluid dynamics principles, but practical application requires balancing theoretical optimization against real-world constraints of weight, flexibility, and cost.

Flow capacity increases with the fourth power of diameter—doubling the inside diameter theoretically increases flow capacity sixteen-fold if pressure remains constant. However, this relationship assumes ideal conditions rarely encountered in field applications. Friction losses, turbulence at connections, and entrance/exit effects all reduce actual flow below theoretical maximums.

Undersizing a pump suction hose creates multiple problems beyond simple capacity limitations. Excessive flow velocity generates turbulence and increases friction losses, forcing the pump to work harder and consuming more energy. More critically, high velocity in the suction line increases the risk of cavitation—the formation and collapse of vapor bubbles that can damage pump components and drastically reduce performance.

Industry best practice recommends maintaining suction line velocity below 5 feet per second for most water applications. This conservative approach ensures adequate flow while minimizing cavitation risk and pressure drop. Calculating the appropriate inside diameter requires knowing the desired flow rate and applying straightforward formulas, yet this critical step frequently receives insufficient attention during initial system design.

Oversizing also presents drawbacks despite seeming conservative. An unnecessarily large rubber water suction hose costs more initially, requires heavier-duty handling equipment, and may prove unwieldy in confined installation spaces. The weight difference between a 4-inch and 6-inch reinforced suction hose becomes significant when considering 50 or 100-foot lengths that crews must deploy regularly.

Working Pressure and Vacuum Rating: Safety Margins Matter

Every rubber suction hose carries dual pressure specifications: maximum working pressure (for discharge applications) and maximum vacuum rating (for suction service). The vacuum rating proves particularly critical for suction applications, as it defines the negative pressure the hose can withstand without collapse.

Vacuum ratings typically appear as inches of mercury (in. Hg) or bar. A rating of 28 in. Hg represents near-absolute vacuum—the theoretical maximum at sea level. Most industrial rubber water suction hose specifications range from 22 to 28 in. Hg, with the higher ratings indicating superior collapse resistance.

The required vacuum rating depends on multiple system factors: pump capacity, suction lift height, friction losses in the line, and elevation above sea level. A deep-well application generating high suction lift demands reinforced suction hose with maximum vacuum resistance. Conversely, a shallow pond transfer with minimal lift allows using lighter-duty hose with lower vacuum ratings.

Applying appropriate safety factors proves essential for reliable operation. While a pump might generate 20 in. Hg maximum vacuum under worst-case conditions, specifying hose rated for 24-26 in. Hg provides margin for variations in operating conditions, gradual material degradation over time, and unexpected situations like partial blockages that temporarily increase vacuum levels.

Failure to respect vacuum ratings leads to predictable consequences. Hose collapse restricts flow, forces the pump to work harder, and may cause complete system failure if the collapse becomes severe. A collapsed rubber suction hose also suffers permanent deformation, requiring replacement even if the immediate crisis passes. The cost of this failure—including downtime, emergency repairs, and premature replacement—far exceeds any initial savings from selecting inadequately rated hose.

Length and Bend Radius: Physical Installation Constraints

The length of a rubber water suction hose affects both initial cost and operational performance. Longer lengths minimize the number of connections required—each coupling represents a potential leak point, flow restriction, and maintenance concern. However, longer sections also increase handling difficulty, require more storage space, and may prove impossible to deploy in confined areas.

Standard manufacturing lengths typically range from 20 to 50 feet, with custom lengths available at premium cost. System designers should evaluate the installation route carefully, identifying opportunities to minimize connections while maintaining practical handling capability. A 200-foot run might be most efficiently served by four 50-foot sections rather than eight 25-foot pieces, reducing connection points from seven to three.

Minimum bend radius specifications often receive insufficient attention during installation planning. Every pump suction hose has a specified minimum bend radius—typically 3 to 5 times the inside diameter—below which permanent damage or performance degradation occurs. Forcing a 6-inch reinforced suction hose around a corner with a 12-inch radius may create localized stress concentrations that reduce vacuum resistance and accelerate fatigue failure.

Planning installation routes must account for these physical constraints. A complex route with multiple direction changes may require additional length to maintain proper bend radii, or might necessitate using more flexible soft suction hose in critical sections despite potentially reduced pressure ratings. The goal is optimizing the entire system rather than simply minimizing hose length without considering installation realities.

Installation Best Water Hose Practices: Setting the Foundation for Reliability

Even the highest-quality rubber water suction hose will underperform if installed improperly. Installation practices directly impact operational efficiency, service life, and long-term maintenance requirements. Understanding and implementing proper installation techniques represents an essential investment in system reliability.

Avoiding Twist and Torsion

Twist represents one of the most common yet completely preventable installation errors. When a rubber suction hose is twisted during installation, the reinforcement structure experiences uneven stress distribution that compromises vacuum resistance and accelerates fatigue damage. Visual identification of twist requires careful attention—the hose layline or printed markings should run straight along the length without spiraling around the circumference.

The proper installation sequence begins with laying out the hose completely straight before making any connections. This allows visual verification that no twist exists in the body of the hose. Only after confirming proper orientation should workers attach end fittings, taking care not to rotate the hose during the coupling process.

Twist often occurs when workers roll out hose from a coil without proper technique. As the hose uncoils, it naturally wants to retain its coiled shape, which can introduce twist if not managed carefully. The correct approach involves rotating the entire coil as the hose unrolls, similar to dispensing rope, rather than pulling hose from a stationary coil. This seemingly minor technique difference prevents twist that would otherwise require disassembling and repositioning connections.

In applications where the pump suction hose must be coiled for storage and repeatedly deployed, special care is essential. Each deployment cycle presents an opportunity to introduce twist if workers don't pay attention to maintaining proper orientation. Training crews in proper handling techniques and implementing visual verification steps—checking that laylines remain straight—prevents accumulated twist damage over multiple deployment cycles.

Coupling Selection and Sealing Technology

The connection between rubber water suction hose and equipment represents a critical interface requiring proper coupling selection and installation technique. Improper connections create vacuum leaks that degrade pump performance, increase energy consumption, and may prevent the system from functioning altogether.

Cam-and-groove couplings dominate quick-connect applications due to their speed and convenience, but they require proper gasket selection and maintenance. The gasket material must be compatible with both the fluid and expected temperature range. EPDM gaskets suit most water applications, while nitrile gaskets prove necessary when hydrocarbon contamination might occur. Regular gasket inspection and replacement prevents air infiltration that compromises suction performance.

Threaded connections offer greater security but require careful installation to avoid over-tightening that damages hose bead or under-tightening that allows leakage. The use of Teflon tape or pipe sealant depends on coupling design—some manufacturers explicitly prohibit sealants that might compromise gasket sealing surfaces or contaminate fluid streams. Always consult manufacturer specifications rather than assuming universal practices apply.

Hose clamps, when used, must be sized correctly and positioned properly. The clamp should compress the rubber water suction hose evenly around the barbed fitting without creating localized stress points that damage the hose wall. Over-tightening actually reduces sealing effectiveness by deforming the hose excessively, while under-tightening allows the hose to blow off under pressure or pull off under vacuum.

A often-overlooked detail involves the direction of hose clamp screws. Positioning screw heads where they're easily accessible facilitates future inspection and adjustment. In applications involving multiple hoses in proximity, consistent clamp orientation simplifies maintenance and reduces the likelihood of missing a loose connection during routine inspections.

Proper Support and Strain Relief

A reinforced suction hose suspended without proper support experiences accelerated wear from its own weight, particularly at connections where stress concentrates. Long horizontal runs require intermediate support at intervals determined by hose size and construction. A general guideline suggests supporting heavy duty suction hoses every 6 to 10 feet, though specific applications may demand closer spacing.

Support methods must avoid creating localized pressure points that damage the hose wall. Wide support cradles or padded saddles distribute weight evenly, while sharp-edged supports create stress concentrations that accelerate fatigue failure. In abrasive environments, protecting the rubber suction hose from contact with rough surfaces extends service life significantly—even robust compounds wear rapidly when constantly rubbing against concrete or steel.

Vertical rises present particular challenges, as the full weight of fluid-filled hose creates substantial tensile stress at the lower connection. Applications involving significant vertical lifts should incorporate strain relief devices or additional support structures that prevent the connection from bearing all the weight. This becomes especially critical with black suction hose in larger diameters, where weight becomes substantial even before considering the fluid column weight.

The pump suction inlet deserves special attention during installation. The connection point must be positioned to avoid creating a sharp bend at the pump flange, which would restrict flow and create turbulence. Allowing the hose to form a gentle, gradual curve from the inlet into the routing path optimizes flow conditions and reduces stress on both the hose and the pump connection.

Water Delivery Hose Material Comparison: Understanding Alternative Options

The dominance of rubber water suction hose in industrial fluid transfer applications stems from specific performance characteristics that alternative materials struggle to match. Understanding these comparisons helps explain why rubber remains the material of choice for demanding suction applications despite the availability of alternatives.

Rubber Versus PVC: The Flexibility Factor

Polyvinyl chloride (PVC) hoses offer cost advantages and excellent chemical resistance for certain applications, but they cannot match the flexibility and vacuum resistance of rubber construction. PVC's rigid molecular structure limits flexibility, particularly at low temperatures where the material becomes brittle and prone to cracking.

A reinforced suction hose constructed from rubber maintains flexibility across a much broader temperature range, remaining supple in cold weather when PVC alternatives become stiff and difficult to handle. This property proves essential for applications requiring frequent deployment or operation in variable climates. Emergency response teams particularly value this characteristic when black suction hose must be deployed rapidly regardless of ambient temperature.

The vacuum resistance of PVC also falls short of rubber's performance in equivalent wall thickness. PVC requires thicker walls or heavier reinforcement to achieve comparable vacuum ratings, offsetting much of its weight advantage. When applications demand high vacuum resistance with reasonable flexibility, rubber suction hose remains the clear choice.

Rubber Versus Polyurethane: Balancing Abrasion Resistance

Polyurethane hoses offer exceptional abrasion resistance that exceeds even the toughest rubber compounds. For applications involving highly abrasive materials, polyurethane's extended wear life justifies its higher initial cost. However, polyurethane lacks the flexibility and elastic recovery of rubber, making it less suitable for applications requiring tight coiling or complex routing.

A rubber water suction hose provides superior flexibility and handling characteristics compared to polyurethane alternatives. The choice between materials depends on whether abrasion resistance or flexibility takes priority for the specific application. Mining operations handling abrasive slurries might accept polyurethane's handling limitations in exchange for extended wear life, while municipal applications prioritizing ease of deployment favor rubber's flexibility despite slightly reduced abrasion resistance.

Rubber Versus Metal Pipe: Mobility and Installation

Rigid metal piping offers durability and pressure capacity but completely lacks the mobility and flexibility that define rubber suction hose utility. Applications requiring frequent reconfiguration, temporary installations, or routing through complex spaces depend fundamentally on flexible hose solutions.

The weight differential also favors rubber significantly. A 50-foot section of 4-inch steel pipe requires mechanical handling equipment, while two workers can easily manage an equivalent rubber water suction hose. This handling advantage translates directly to reduced installation costs and faster deployment in emergency or temporary applications.

Conclusion: Suction Hose Engineering Success Through Informed Selection

The humble rubber water suction hose represents far more than a commodity component connecting pumps to water sources. It embodies sophisticated material science, careful engineering design, and decades of manufacturing refinement aimed at reliably conquering the unique challenges of negative-pressure fluid transfer.

Success in fluid transfer applications demands respect for the technical complexity behind these essential components. Material selection between natural rubber, SBR, EPDM, or specialized compounds directly determines performance in specific operating environments. The critical parameters of inside diameter, vacuum rating, and physical dimensions must align precisely with system requirements rather than representing arbitrary choices or simple cost optimization.

Installation quality establishes the foundation for long-term reliability, with proper technique preventing twist, ensuring vacuum-tight connections, and providing adequate physical support. These practices transform even premium reinforced suction hose into a reliable system component that delivers years of trouble-free service rather than recurring maintenance headaches.

The engineering sophistication invested in modern rubber suction hose deserves recognition and respect during selection and installation processes. When treated as the precision-engineered component it is rather than a simple commodity, a properly specified pump suction hose becomes an invisible asset—performing flawlessly year after year while more glamorous equipment components receive attention.

For operations dependent on reliable fluid transfer, investing time in understanding these technical elements pays dividends through reduced downtime, lower maintenance costs, and elimination of the production delays that occur when inadequate hose selection or improper installation compromises system performance. The difference between merely adequate and truly excellent fluid transfer systems often comes down to these fundamental details that separate commodity purchasing from engineering excellence. Evergood has been in water suction hose area for more than 16 years, any help, contact us.

Leave a comment

Comments

-

rubber suction hose

By: Inigo On 01/23/2026This blog provides expert tips on selecting the ideal rubber suction hose to prevent vacuum collapse. A must-read for anyone looking to ensure efficient fluid transfer and long-lasting performance in demanding industrial applications!

Latest comments