This air hose buying guide explores essential pneumatic hose materials (Poly, Rubber,Hybrid, PVC), diameters, and...

Important Key Factor influencing Hydraulic Hose Assembly You Can Not Miss

Important Key Factor Influencing Hydraulic Hose Assembly

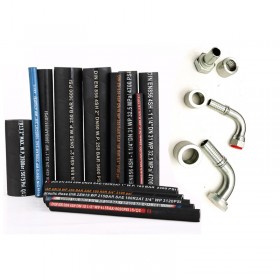

Because most people are not professional hydraulic hose repairers, buying a hydraulic hose assembly becomes your first choice. So do you know what is the most important factor effect on hydraulic hose and fittings?

Yes, it is temperature! When hydraulic hose assembly is exposed to extreme cold or extreme heat, their performance may change drastically. During these exposures, plan to rate hoses at lower working pressures to prevent short-term and long-term damage. Especially the fittings of the hydraulic hose assembly will be greatly affected.

Temperature Influencing Hydraulic Fitting

The following are two very popular steel hydraulic fittings. When choosing to purchase hydraulic hose assemblies, please consider the characteristics of these fittings.

Carbon steel hydraulic fittings : This alloy steel combines carbon and iron. It is inexpensive and can withstand extremely high heat and high pressure. It is most commonly used in hydraulic equipment in construction, agriculture and industrial applications.

Stainless steel hydraulic fittings : It can withstand extremely low and high temperatures. This is a good choice for oil and gas applications, chemical processing, and many other applications. In addition, this alloy can resist corrosion and rust both internally and externally. If corrosion is likely to occur, stainless steel hydraulic fittings are your best choice.

Choose The Best Hydraulic Hose Assembly Fit You

According to the different characteristics of hydraulic pipe fittings, combined with your own working environment, please purchase the hydraulic hose assembly that suits you.

In addition, if the hydraulic hose assembly is working in extremely cold and extremely hot environments for a long time, it is best to purchase a suitable hydraulic hose protective guard to alleviate the sharp change in temperature. This can extend the service life of the hydraulic hose assembly. Nevertheless, it is still necessary to regularly check the hydraulic hoses for signs of deterioration. Replace it in time to avoid huge losses.

If you intend to operate a high-pressure hydraulic hose assembly in a strict environment, our team at Evergood hopes to make the best decision for your operation based on the hydraulic hose and fittings you choose. Contact us today to discuss our options and learn more about our ordering process.

Hydraulic Hose Assembly Quality Inspection Tips

Finally, I will share with you some of our basic production standards for hydraulic hose assemblies. Welcome to inquire.

1. The surface of the hydraulic hose assembly is not allowed to have cracks, burrs, flashes, uneven marks, scratches, rust and other defects that affect product quality.

2. The seizure of the hydraulic hose and fittings should be flat, the inner wall should be smooth and unblocked, and the inner rubber layer should not be strained.

3. The outer layer of the hose should have no visible defects

Leave a comment

Comments

-

hydraulic hose assembly

By: Mateo On 01/13/2026"This article provides a deep yet accessible analysis of the key factors influencing hydraulic hose assembly. It is professional and practical, covering core essentials from pressure ratings to environmental adaptability. It serves as an invaluable reference for technicians and buyers looking to enhance equipment safety and extend service life.

Latest comments